A torque spanner wrench is a tool used to apply a specific torque to a fastener. It ensures accurate tightness and prevents over-tightening.

A torque spanner wrench, often known as a torque wrench, is essential in mechanical and automotive tasks. This tool allows precise control over the tightness of bolts and nuts, ensuring they are neither too loose nor overly tight. Correct torque application is crucial in various industries to maintain safety and performance standards.

Using a torque wrench minimizes the risk of equipment failure due to improperly tightened fasteners. Available in different types, including beam, click, and digital, torque wrenches are versatile and user-friendly. Investing in a high-quality torque wrench ensures reliable, long-lasting performance in any mechanical setting.

Credit: www.heatstaking.com

Introduction To Torque Spanner Wrench

A torque spanner wrench is an essential tool in various industries. It ensures bolts and nuts are tightened to precise specifications. This tool helps prevent damage and ensures safety.

Purpose And Importance

The primary purpose of a torque spanner wrench is to apply a specific amount of force to fasteners. This is crucial in many applications:

- Automotive Industry: Ensures wheel nuts are properly tightened.

- Aerospace: Critical for aircraft assembly and maintenance.

- Construction: Helps in structural integrity of buildings.

- Machinery: Ensures bolts in machines are secure.

Using a torque spanner wrench guarantees that fasteners are neither too loose nor too tight. This prevents potential failures and extends the lifespan of the equipment. Precision is key, and this tool delivers just that.

History And Development

The torque spanner wrench has a rich history. It dates back to the early 20th century. The first versions were simple mechanical devices. Over time, they evolved into more sophisticated tools.

| Era | Development |

|---|---|

| 1920s | Introduction of basic mechanical torque wrenches. |

| 1940s | Widespread use in automotive and aviation industries. |

| 1980s | Introduction of digital torque wrenches. |

| 2000s | Enhanced accuracy and user-friendly designs. |

Modern torque spanner wrenches feature advanced materials and digital displays. These advancements ensure greater accuracy and ease of use. The evolution of this tool highlights its importance in various sectors.

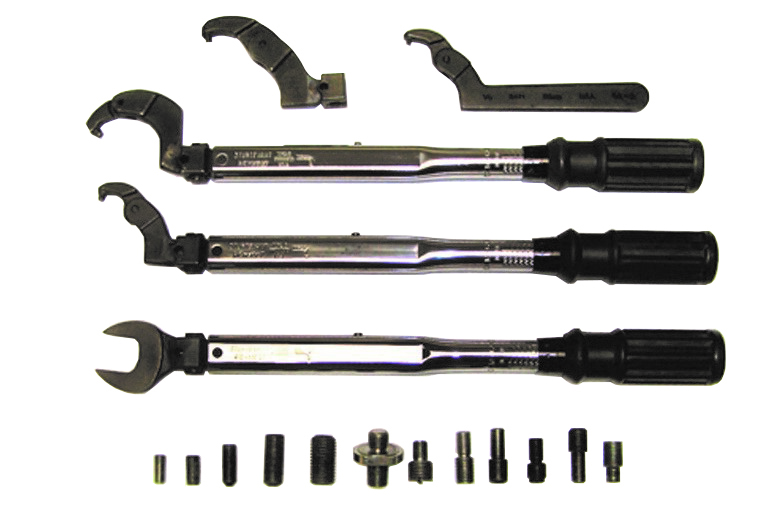

Types Of Torque Spanner Wrenches

Torque spanner wrenches are essential tools in many industries. They ensure bolts and nuts are tightened to the right level. Different types of torque spanner wrenches exist. Each type serves unique needs. Let’s explore the main types.

Click Type

The click type torque wrench is very popular. It makes a clicking sound when the set torque is reached. This type is easy to use. It is accurate and reliable.

- Sound Alert: Click sound when torque is reached.

- Ease of Use: Simple to operate.

- Accuracy: High accuracy for precise work.

Beam Type

The beam type torque wrench is very simple. It has a scale and a pointer. As you tighten, the pointer moves. This shows the torque level. It is cost-effective and durable.

- Simplicity: Basic design with no moving parts.

- Durability: Long-lasting and tough.

- Cost-Effective: More affordable than others.

Digital Type

The digital type torque wrench is modern. It has a digital display. This shows the exact torque value. It can store data and give alerts. It is very precise and easy to read.

- Digital Display: Shows exact torque value.

- Data Storage: Keeps records of previous uses.

- Precision: Highly accurate readings.

How Torque Spanner Wrenches Work

Torque spanner wrenches are essential tools for precision work. They ensure bolts and nuts are tightened to the correct torque. Understanding their operation helps in achieving the best results.

Mechanism Of Operation

A torque spanner wrench uses a simple yet effective mechanism. The wrench has a handle and a head that grips the fastener. Inside the handle, there is a spring-loaded lever.

When you apply force, the lever compresses the spring. This compression measures the force applied. The wrench clicks when the set torque is reached. This click indicates that you should stop applying force.

The mechanism ensures accurate torque application. It prevents over-tightening or under-tightening.

Measuring Torque

Measuring torque is vital in various applications. Torque spanner wrenches come with either analog or digital displays. Analog wrenches have a dial gauge that shows the torque value. Digital wrenches have an LCD screen displaying the torque.

Both types provide accurate measurements. Analog wrenches are simple to use and maintain. Digital wrenches offer more features like memory settings and alerts.

Here is a table comparing analog and digital torque spanner wrenches:

| Feature | Analog | Digital |

|---|---|---|

| Display | Dial Gauge | LCD Screen |

| Accuracy | High | Very High |

| Ease of Use | Simple | Advanced |

| Features | Basic | Memory, Alerts |

Choosing between analog and digital depends on your needs. Both ensure the correct torque is applied.

Using a torque spanner wrench correctly is crucial. Always read the user manual and follow the instructions. This ensures the longevity and accuracy of the tool.

Credit: www.jharlen.com

Choosing The Right Torque Spanner Wrench

Choosing the right torque spanner wrench is crucial for any mechanic or DIY enthusiast. It ensures the correct tightness of bolts and prevents damage. This section guides you through the essentials of selecting the perfect wrench.

Factors To Consider

When picking a torque spanner wrench, several factors come into play:

- Accuracy: Ensure the wrench provides precise measurements.

- Range: Check the torque range to match your needs.

- Durability: Look for robust materials like steel or alloy.

- Comfort: A comfortable grip reduces strain during use.

- Price: Balance cost with quality and features.

Different tasks require different torque ranges. Make sure your wrench covers the required range for your projects.

Popular Brands

Several brands are well-known for their quality torque spanner wrenches. Here are a few:

| Brand | Features |

|---|---|

| Snap-On | High accuracy, durable, ergonomic design |

| Craftsman | Affordable, reliable, good warranty |

| GearWrench | Wide range, quality materials, digital options |

Choose a brand that fits your budget and meets your quality expectations. Popular brands often provide warranties and excellent customer service.

Proper Usage Techniques

Using a torque spanner wrench correctly ensures the longevity of your tools and the safety of your projects. By following the proper usage techniques, you can achieve precise and consistent torque settings. This guide will help you understand the best practices for setting the torque and using the wrench correctly.

Setting The Torque

Setting the torque correctly is the first step. Follow these steps:

- Identify the required torque for your project.

- Refer to the manufacturer’s manual for specifications.

- Locate the adjustment dial on the wrench handle.

- Turn the dial to match the required torque setting.

- Ensure the dial clicks into place.

Different projects require different torque settings. Always verify your settings before use.

Using The Wrench Correctly

Correct usage of the torque spanner wrench is crucial. Follow these steps:

- Position the wrench on the bolt or nut.

- Apply steady pressure while turning the wrench.

- Listen for a click sound indicating the set torque is reached.

- Stop applying force immediately after the click.

- Double-check your work to ensure proper tightness.

Using the wrench correctly prevents over-tightening. It also avoids damaging the fasteners.

| Task | Required Torque (Nm) |

|---|---|

| Car wheel bolts | 100-120 |

| Bicycle handlebars | 5-8 |

| Engine parts | 20-80 |

Always refer to the manufacturer’s guidelines. This helps in selecting the correct torque settings.

By following these steps, you ensure safe and effective use of your torque spanner wrench.

Credit: www.hoffmann-group.com

Maintenance And Calibration

Maintaining and calibrating your torque spanner wrench ensures its accuracy and longevity. Regular care keeps it functioning properly, while calibration maintains its precision.

Regular Maintenance Tips

Proper maintenance of your torque spanner wrench involves several steps. Following these tips can help extend its life:

- Clean the wrench after each use with a soft cloth.

- Store it in a protective case to avoid damage.

- Lubricate the moving parts periodically.

- Check for any signs of wear or damage.

- Never exceed the wrench’s maximum torque rating.

Calibration Procedures

Calibration ensures your wrench delivers accurate torque readings. Follow these steps to calibrate your torque spanner wrench:

- Secure the wrench in a calibration device.

- Apply a known torque value to the wrench.

- Compare the wrench’s reading with the known value.

- Adjust the wrench if the readings do not match.

- Re-test to confirm accuracy.

| Maintenance Task | Frequency |

|---|---|

| Cleaning | After each use |

| Lubrication | Monthly |

| Calibration | Every 6 months |

Common Mistakes To Avoid

Using a torque spanner wrench is essential for tightening bolts correctly. Many people make mistakes that can cause damage. Learn how to avoid these common errors.

Over-tightening

Over-tightening bolts is a frequent mistake with a torque spanner wrench. This can cause threads to strip or even break the bolt.

To avoid over-tightening:

- Always set the correct torque level.

- Listen for the wrench’s click.

- Stop tightening immediately after the click.

Over-tightening can also damage the parts being joined. This reduces the lifespan of your equipment.

Under-tightening

Under-tightening is another common issue. Bolts that are too loose can come undone. This can cause parts to separate.

To avoid under-tightening:

- Double-check the torque setting.

- Ensure the wrench is calibrated.

- Apply steady, even pressure.

Under-tightening can lead to safety hazards. Always make sure bolts are properly tightened.

By avoiding these mistakes, you can ensure the longevity and safety of your equipment.

Applications In Various Industries

The torque spanner wrench is a versatile tool. It finds applications across multiple industries. Each industry uses it for specific purposes. Below are the main industries that use this tool.

Automotive Industry

In the automotive industry, the torque spanner wrench is crucial. It ensures that bolts and nuts are tightened correctly. This tool helps in avoiding over-tightening or under-tightening. Mechanics use it to maintain vehicle safety. Here are some specific applications:

- Engine assembly

- Wheel fitting

- Suspension systems

- Transmission components

Aerospace Industry

The aerospace industry demands high precision. The torque spanner wrench meets this need. It ensures the integrity of aircraft components. Technicians use it to maintain tightness standards. Here’s how it’s used in aerospace:

- Assembling airframe structures

- Fitting landing gear

- Engine assembly and maintenance

- Securing avionics systems

Construction

In the construction industry, the torque spanner wrench is essential. It ensures the structural integrity of buildings. Workers use it to tighten bolts in metal frameworks. This tool is also used in heavy machinery assembly. Some applications include:

- Steel frame construction

- Bridge assembly

- Heavy machinery maintenance

- Scaffolding setup

Frequently Asked Questions

What Is A Torque Spanner Used For?

A torque spanner is used to apply a specific amount of force to a fastener, ensuring proper tightness. It prevents over-tightening or under-tightening, which can cause damage. Ideal for automotive, machinery, and construction tasks.

How Do You Use A Spanner With A Torque Wrench?

To use a spanner with a torque wrench, attach the appropriate socket to the wrench. Adjust the torque setting. Securely fit the socket on the bolt or nut. Apply force until the wrench clicks or signals the set torque is reached.

Ensure accurate, consistent tightening by following the wrench’s instructions.

What Are The 4 Types Of Torque Wrenches?

The four types of torque wrenches are click, beam, digital, and dial. Each offers unique benefits for specific applications.

What Is The Difference Between A Wrench And A Torque Wrench?

A wrench tightens or loosens bolts and nuts. A torque wrench measures and applies specific torque to fasteners.

Conclusion

A torque spanner wrench is essential for precise fastening. It ensures bolts are tightened to exact specifications. This tool prevents over-tightening and potential damage. Investing in a quality torque spanner wrench enhances safety and efficiency. Choose the right one for your needs and enjoy reliable, accurate results every time.