Executive Summary

This case study analyzes a critical accident involving a Grade-1 Lineman from a Palli Bidyut Samity (PBS) Zonal Office on April 19, 2015. The incident serves as a stark reminder that in high-voltage work, partial isolation is never a substitute for a full safety protocol.

1. The Incident Overview

At 10:15 AM, the lineman arrived at a site to repair a snapped High-Tension (HT) conductor. Due to the absence of a nearby sectionalizing point, a backbone shutdown was technically required. To expedite the repair, the lineman opted for a shortcut:

-

The Action: He took a brief shutdown, disconnected only the Yellow (Y) Phase jumper at the C-26 fitting, and immediately requested the line to be re-energized.

-

The Intent: He planned to splice the wire on the ground and then climb the pole to reconnect it, believing that since the Yellow phase was disconnected, he was safe.

2. The Chain of Failure

While the lineman was pulling the wire on the ground to prepare for the splice:

-

The mechanical tension caused the wire to slip from the C-7 fitting (four poles away from the transformer bank).

-

The released wire recoiled and made direct contact with the energized Red (R) Phase.

-

The lineman, holding the conductor on the ground, became the path to earth for the high-voltage current.

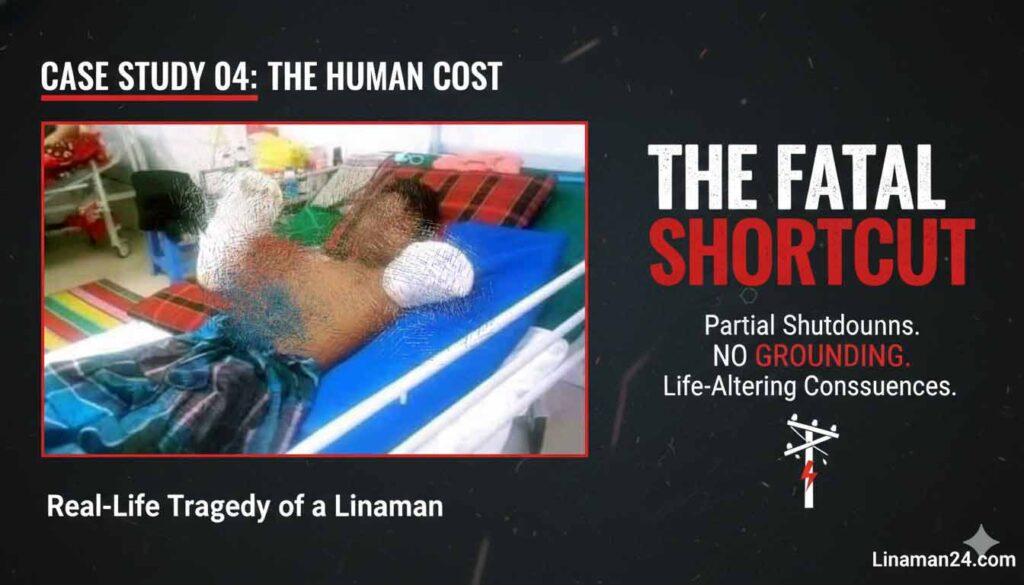

Outcome: The victim survived the initial shock but suffered catastrophic electrical burns, resulting in the amputation of both arms.

“The following images and case study are shared for educational purposes to prevent future accidents. Viewer discretion is advised.”

3. Root Cause Analysis (RCA)

-

Inadequate Isolation: The decision to work near live phases (Red and Blue) while only disconnecting the Yellow phase violated the “Minimum Approach Distance” and isolation standards.

-

Absence of Temporary Grounding: No grounding sets were applied. Had the wire been grounded, the fault current would have been diverted to the earth instead of passing through the lineman’s body.

-

Mechanical Oversight: Underestimating the “snap-back” or tension effect of a conductor when handled manually near live lines.

-

Process Violation: Re-energizing the backbone before the work was completed and cleared.

4. Safety Recommendations & Global Protocols

To prevent such life-altering tragedies, the following international safety standards must be strictly enforced:

-

The “All-Phase” Rule: Never treat a circuit as “dead” if only one phase is disconnected. Always isolate all three phases for any repair work on the backbone.

-

Mandatory Grounding (The Invisible Shield): Temporary grounding sets must be installed on the work side and the source side. If it’s not grounded, it’s not dead.

-

Full Feeder Shutdown: For high-risk tasks like wire splicing and pulling, the entire feeder must remain under a locked-out/tagged-out (LOTO) shutdown until the job is verified complete.

-

Tension Control: Use proper mechanical grips and stay clear of the potential “swing path” of a conductor under tension.

Final Word

Safety is not about how fast you finish the job; it’s about ensuring you are there to do the next one. This case study proves that shortcuts in the field lead to dead ends in life.

Read More….. Safety First, Work Last: Lessons from 12 Years as a Lineman