Hey there, Do you know how many lineman die a year? let’s talk about something important. These are the people who keep our electricity and communication systems running smoothly. But their job? It’s pretty risky.

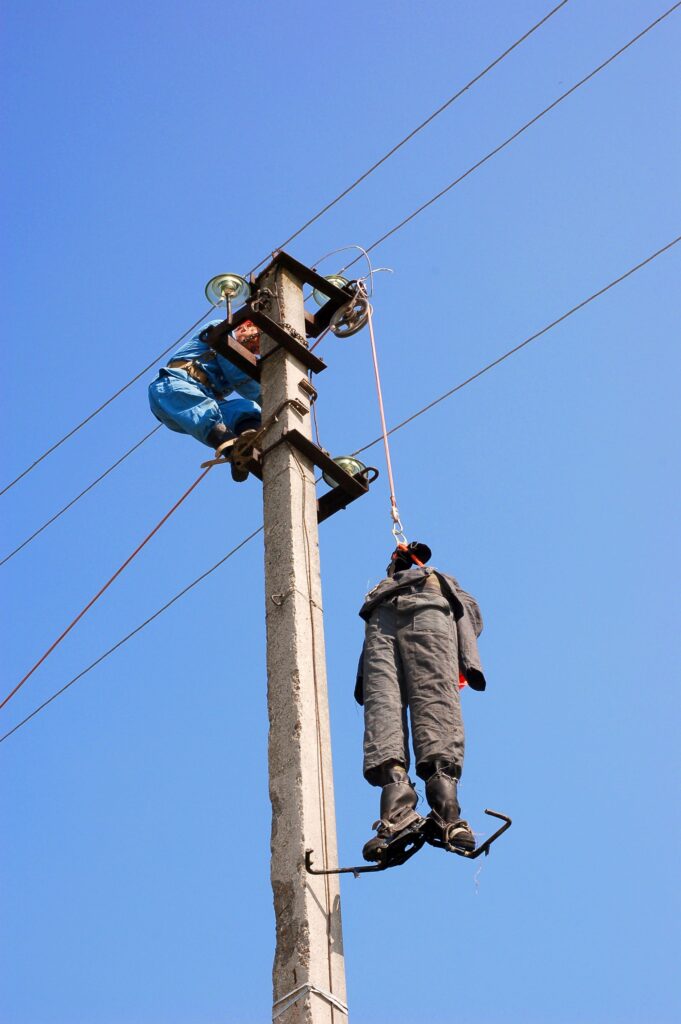

Statistics from national lineman surveys and utility company records reveal that a staggering 42 linemen out of every 100,000 lose their lives on the job annually, making their profession one of by logging and agricultural labor. The unique combination of high-voltage electricity and elevated work environments creates a perilous work setting. Furthermore, the ever-changing weather conditions pose an additional threat. Despite significant advancements in power and utility safety over the past five years, with numerous innovations and solutions being introduced each year to enhance worker safety and training, accidents still occur, highlighting the extremely low tolerance for error in this line of work.

The good news? We can do something about it. We need to push for better safety measures and new technology to protect these brave workers. It’s time to make their job safer. They deserve it.

So, let’s dig into why their work is so risky. More importantly, we need to know what we can do to help. It’s essential work, but it’s time to make sure it’s done safely.

Understanding The Risks: How Dangerous Is The Lineman Profession?

The lineman profession faces significant dangers, with about 30 to 50 fatalities each year. High-voltage work and extreme weather conditions contribute to these risks.

The lineman profession is one of the most hazardous jobs. Workers face many risks daily to keep our power running. Let’s explore the dangers these brave individuals encounter.

Physical Risks

Lineman work involves strenuous physical tasks. Here are some physical risks they face:

- Electrocution: Contact with live wires.

- Falls: Working from high poles or towers.

- Heavy lifting: Moving and installing heavy equipment.

- Extreme weather: Working in severe conditions.

Health Concerns

Exposure to various elements can impact linemen’s health. They often work in challenging environments that can lead to health issues.

Safety Measures

Safety measures are crucial in this profession. Proper training and equipment can significantly reduce risks:

- Safety gear: Helmets, gloves, and boots.

- Regular training: Keeping skills up-to-date.

- Strict protocols: Following safety guidelines.

- Teamwork: Ensuring everyone looks out for each other.

Mental Stress

The job also takes a toll on mental health. Linemen often face high-stress situations, such as:

- Emergency response: Handling urgent power outages.

- Long hours: Extended shifts during crises.

- High responsibility: Ensuring public safety.

- Isolation: Working alone or in small teams.

Industry Statistics

Statistics provide insight into the dangers faced by linemen. These numbers highlight the importance of safety in this field:

- Fatalities: Number of deaths per year.

- Injuries: Common injuries reported.

- Safety improvements: Impact of new safety measures.

- Comparative risk: Lineman vs. Other professions.

Understanding these risks is vital. It emphasizes the importance of safety and appreciation for linemen’s hard work.

Why Linemen Face High Workplace Hazards

Linemen face high workplace hazards due to working with high voltage electricity and climbing tall structures. Each year, around 30 to 50 linemen die on the job. Safety measures are crucial to protect these workers.

Linemen work in high-risk environments. Every day, they face numerous hazards that can lead to severe injuries or even death. Understanding these risks is crucial for improving their safety measures.

Working At Heights

Linemen often work high above the ground. This poses significant risks.

- Fall hazards: Linemen work on poles and towers.

- Safety gear: Essential to prevent falls.

- Weather conditions: Can make heights even more dangerous.

Electrical Hazards

Electricity is a constant danger. Linemen handle live wires regularly.

- Electrocution risk: Contact with live wires.

- Burns: Electrical burns are severe.

- Arc flashes: Can cause serious injuries.

Extreme Weather

Linemen work in all weather conditions. This includes storms and extreme temperatures.

- Wind and rain: Make tasks more challenging.

- Heat and cold: Extreme temperatures can affect performance.

- Lightning: Poses a direct threat during storms.

Heavy Equipment

Heavy machinery is part of a lineman’s daily job. Operating this equipment carries risks.

- Equipment malfunction: Can cause accidents.

- Moving parts: Risk of getting caught or crushed.

- Transportation: Accidents can occur while moving equipment.

High-pressure Situations

Linemen often work under tight deadlines. This pressure can lead to mistakes.

- Time constraints: Increase stress and risk of errors.

- Emergency repairs: Require quick action in dangerous conditions.

- Fatigue: Long hours can lead to accidents.

By understanding these hazards, we can work towards safer conditions for linemen.

Key Causes Behind Lineman Fatalities Every Year

Lineman fatalities occur due to high-risk factors such as electrical shocks, falls, and equipment failures. Each year, around 30 to 50 linemen lose their lives on the job. Safety measures and proper training are crucial to reduce these tragic incidents.

Working as a lineman is a dangerous job. Every year, many face life-threatening risks. The fatalities among linemen are alarming and understanding the key causes can help in prevention.

Electrocution

Electrocution is a leading cause of lineman deaths. It’s a constant hazard in their work environment.

- High Voltage: Linemen work with high-voltage lines that can be deadly.

- Poor Insulation: Faulty insulation can result in electric shocks.

- Unsafe Equipment: Using damaged tools increases the risk of electrocution.

Falls From Heights

Linemen often work at great heights. Falls are a significant cause of fatalities.

Falls can occur due to various reasons:

- Unstable Platforms: Working on shaky surfaces can lead to falls.

- Lack of Safety Gear: Not using harnesses or helmets increases risk.

- Slippery Conditions: Wet or icy conditions make work areas hazardous.

Traffic Accidents

Traffic accidents happen frequently. Linemen often work near busy roads.

- Distracted Drivers: Drivers not paying attention pose a threat.

- Poor Visibility: Working at night or in bad weather increases risk.

- Inadequate Signage: Lack of warning signs can lead to accidents.

Contact With Heavy Machinery

Linemen use heavy machinery. This machinery can be dangerous if not handled properly.

- Equipment Malfunction: Faulty machines can cause fatal accidents.

- Improper Training: Lack of training leads to mishandling equipment.

- Mechanical Failure: Unexpected breakdowns can have deadly results.

Overexertion And Fatigue

Excessive physical effort and tiredness can be deadly. Linemen often work long, strenuous hours.

- Long Shifts: Extended work hours lead to exhaustion.

- Extreme Weather: Working in harsh conditions affects performance.

- Insufficient Breaks: Lack of rest increases the risk of mistakes.

Understanding these key causes can lead to better safety measures. It’s crucial to ensure linemen are protected while performing their vital roles.

Comparing Lineman Death Rates To Other High-risk Jobs

Lineman jobs are dangerous, with about 42 deaths each year. This makes it one of the most deadly professions. Comparing this to other high-risk jobs shows how hazardous this field can be.

Working as a lineman is one of the most dangerous jobs. This section will compare the death rates of linemen with other high-risk occupations. Understanding these comparisons can shed light on the risks faced by linemen.

Lineman Death Rates

Lineman death rates are alarmingly high. Here are some key points:

- Annual fatalities: Around 30 to 50 linemen die each year.

- Common causes: Electrocution, falls, and equipment-related accidents.

- Safety measures: Training and protective gear are essential.

Construction Workers

Construction workers also face significant dangers on the job. Let’s look at some statistics:

- Annual fatalities: Over 1,000 deaths each year.

- Major risks: Falls, being struck by objects, and machinery accidents.

- Safety protocols: Hard hats, harnesses, and strict regulations.

Firefighters

Firefighters are known for their bravery, but their job is risky too. Here’s a closer look:

- Annual fatalities: Roughly 70 to 100 firefighters die each year.

- Main dangers: Burns, smoke inhalation, and building collapses.

- Safety equipment: Fire-resistant clothing and breathing apparatuses.

Police Officers

Police officers encounter life-threatening situations regularly. Consider these points:

- Annual fatalities: Around 100 to 150 police officers die each year.

- Primary threats: Gun violence, car accidents, and physical confrontations.

- Protective measures: Bulletproof vests and tactical training.

Fishermen

Commercial fishing is another perilous profession. Key statistics include:

- Annual fatalities: Approximately 50 to 100 fishermen die each year.

- Main hazards: Drowning, equipment failure, and severe weather.

- Safety practices: Life jackets and emergency drills.

Pilots

Pilots also face high risks, particularly in certain sectors. Important details:

- Annual fatalities: About 70 to 100 pilots die each year.

- Common dangers: Mechanical failures, weather conditions, and pilot error.

- Safety protocols: Regular maintenance and rigorous training.

Farmers And Agricultural Workers

Farmers and agricultural workers deal with various risks daily. Key information:

- Annual fatalities: Roughly 400 deaths each year.

- Main risks: Machinery accidents, animal attacks, and pesticide exposure.

- Safety measures: Proper training and protective equipment.

Understanding these comparisons helps highlight the unique dangers linemen face. Each profession has its own set of risks, but linemen remain among the most vulnerable.

Safety Protocols That Could Reduce Lineman Deaths Annually

Each year, many linemen face dangerous work conditions that lead to fatalities. Implementing strict safety protocols could significantly reduce these yearly deaths.

Safety is paramount for linemen. While the job is risky, proper protocols can save lives. Emphasizing safety measures can significantly reduce annual fatalities.

Regular Training Programs

Regular training is essential for linemen. These programs ensure they are always up-to-date.

- Hands-on practice: Real-life scenarios to prepare for actual conditions.

- Updated guidelines: New safety protocols and industry standards.

- Emergency response: Quick and effective actions during accidents.

- Equipment usage: Proper handling and maintenance of tools.

Use Of Personal Protective Equipment (ppe)

Personal protective equipment is crucial. It acts as the first line of defense.

- Helmets: Protects head from falling objects.

- Gloves: Insulates against electrical shocks.

- Boots: Offers grip and prevents slips.

- Safety vests: Enhances visibility in low-light conditions.

Adherence To Safety Regulations

Following safety regulations is non-negotiable. These rules are designed to protect lives.

- OSHA standards: Set by the Occupational Safety and Health Administration.

- Company policies: Specific guidelines unique to each organization.

- Regular audits: Ensures continuous compliance and improvement.

Implementation Of Safety Technologies

Technology can greatly enhance safety. Modern tools and systems can predict and prevent accidents.

- Drones: Inspect hard-to-reach areas safely.

- Sensors: Detect electrical faults before they cause harm.

- Communication devices: Immediate contact in case of emergencies.

- Augmented reality (AR): Provides virtual training scenarios.

Encouraging A Safety Culture

A strong safety culture is vital. Everyone must prioritize safety in their daily tasks.

- Safety meetings: Regular discussions on potential hazards.

- Incentives: Rewards for maintaining safety standards.

- Feedback system: Open channels for reporting safety concerns.

- Role models: Senior staff demonstrating safe practices.

Proper Maintenance Of Equipment

Well-maintained equipment reduces risks. It ensures tools function correctly.

- Routine checks: Regular inspection for wear and tear.

- Timely repairs: Fixing issues before they become dangerous.

- Upgrades: Replacing outdated equipment with modern alternatives.

- Cleaning: Keeping tools free from contaminants.

Monitoring Weather Conditions

Weather affects the safety of linemen. Monitoring can prevent weather-related incidents.

- Forecast checks: Daily updates on weather conditions.

- Safety protocols: Adjusting tasks based on weather.

- Protective shelters: Immediate refuge during sudden weather changes.

- Alert systems: Warns about severe weather threats.

Comprehensive Safety Manuals

Safety manuals provide crucial information. They guide linemen on best practices.

- Detailed instructions: Step-by-step safety procedures.

- Emergency plans: Actions to take during incidents.

- Contact information: Quick access to emergency services.

- Updates: Regular revisions to include new safety measures.

Incorporating these safety protocols can help reduce the number of lineman deaths each year. Following these measures ensures a safer working environment for everyone involved.

Real Stories: Remembering Fallen Linemen

Each year, about 30 to 50 linemen lose their lives while working. These brave individuals face dangerous conditions daily. Their stories remind us of the risks they take to keep our power on.

Every year, communities are shaken by the loss of linemen. These brave individuals risk their lives to ensure our power stays on, often facing dangerous conditions. Here, we remember some of the fallen heroes and their stories.

A Father’s Sacrifice

One lineman, John, was a father of three. He worked tirelessly to provide for his family.

- Dedication to family: John worked long hours to ensure his children had a better future.

- A tragic accident: One stormy night, John was electrocuted while fixing a power line.

- Community impact: His death left a void in the community, highlighting the dangers linemen face daily.

A Hero’s Last Call

Maria, a seasoned lineman, answered her last call during a severe storm. She was known for her bravery.

- Years of service: Maria had over 20 years of experience in the field.

- The final storm: She was struck by lightning while restoring power during a storm.

- Honoring her memory: Her colleagues remember her as a dedicated and fearless worker.

A Young Lineman’s Dream Cut Short

Jake, a young apprentice lineman, had big dreams. He wanted to make a difference.

- Ambitious goals: Jake aimed to become the best lineman in his team.

- An unexpected tragedy: He fell from a pole while working on a high-voltage line.

- Remembering Jake: His passion and enthusiasm are still cherished by those who knew him.

A Veteran’s Last Stand

Paul, a lineman with decades of experience, met his end during a routine repair.

- Decades of service: Paul was a mentor to many young linemen.

- The fateful day: A faulty wire led to a fatal electrocution during a repair.

- Community tribute: Paul’s legacy lives on through the many he trained and inspired.

These stories remind us of the risks linemen face. Their sacrifices ensure our daily lives remain uninterrupted.

The Role Of Training And Equipment In Preventing Lineman Fatalities

Training and proper equipment play crucial roles in reducing lineman fatalities, which occur at a concerning rate each year. Many linemen lose their lives annually due to inadequate safety measures.

Working as a lineman is dangerous. Training and equipment are crucial for safety. Proper training helps linemen avoid mistakes. Using the right gear can prevent injuries or death. This section explores how training and equipment save lives.

Importance Of Rigorous Training

Training ensures linemen know safety protocols. They learn the right procedures to follow. This helps reduce accidents.

- Safety drills: Regular practice builds muscle memory.

- Knowledge of hazards: Linemen learn to identify risks.

- Emergency response: Quick actions can save lives.

Essential Safety Equipment

The right equipment protects linemen. Gear can mean the difference between life and death.

- Insulated gloves: Protect against electrical shocks.

- Hard hats: Prevent head injuries from falling objects.

- Safety harnesses: Keep linemen secure at heights.

Continuous Education And Refresher Courses

Staying updated is vital. New techniques and tools emerge regularly. Refresher courses keep linemen informed.

- Latest safety practices: Learn new methods for staying safe.

- Updated tools: Understanding how to use new gear.

- Reinforcement of basics: Ensures no one forgets key practices.

Role Of Employers In Ensuring Safety

Employers play a big role in safety. They need to provide proper training and equipment.

- Regular safety checks: Ensure gear is in good condition.

- Mandatory training sessions: Keep skills sharp and up-to-date.

- Supportive environment: Encourage reporting of safety concerns.

Real-life Impacts Of Proper Training And Equipment

Proper training and equipment save lives. Real stories show their importance.

- Reduced fatality rates: Fewer deaths with better training.

- Lower injury rates: Proper gear prevents injuries.

- Improved morale: Workers feel safer and more confident.

Proper training and equipment are crucial. They reduce risks and save lives. Employers must ensure linemen have both. Safety should always come first.

Linemen And Electrical Hazards: A Deadly Combination

Linemen face serious risks every day. Around 30 linemen die each year due to electrical hazards. Safety measures are crucial for their protection.

Working as a lineman is a high-risk job. These workers face numerous dangers daily. Their duties involve dealing with electrical hazards, making the profession one of the most dangerous.

The Nature Of Electrical Hazards

Electrical hazards pose serious threats to linemen. These dangers can lead to severe injuries or fatalities.

- Electrocution: Direct contact with live wires can cause death.

- Arc Flashes: High temperatures from electrical arcs can result in burns.

- Electrical Burns: Severe burns from electrical currents can be life-threatening.

- Falls from Heights: Working on power lines involves climbing poles, increasing fall risks.

- Explosions: Faulty equipment can cause explosions, leading to fatal injuries.

Training And Safety Measures

Proper training and safety measures are crucial. They help reduce the risk of electrical hazards.

Linemen receive extensive training. They learn to handle high-voltage equipment. Safety protocols are strictly followed. These include wearing protective gear and using insulated tools. Regular safety drills are also conducted. These drills prepare linemen for emergency situations.

Common Causes Of Lineman Deaths

Understanding the common causes can help in prevention. Most lineman fatalities result from a few specific scenarios.

- Contact with Live Wires: Accidental contact with live wires is a leading cause.

- Lack of Proper Safety Gear: Not using safety gear increases the risk of fatal injuries.

- Inadequate Training: Poor training can lead to mistakes and accidents.

- Weather Conditions: Adverse weather can complicate tasks and increase risks.

- Fatigue: Long hours can lead to fatigue, causing errors.

Importance Of Safety Regulations

Safety regulations play a vital role. They help in minimizing risks associated with electrical hazards.

Strict regulations are enforced. These include mandatory safety gear and equipment checks. Regular inspections ensure compliance. Violations of these regulations result in penalties. These measures aim to protect linemen and reduce fatalities.

By understanding these aspects, we can appreciate the risks linemen face. This knowledge also underscores the importance of safety measures in this dangerous profession.

Year-by-Year Analysis: Trends in Lineman Fatalities

A year-by-year analysis of lineman fatalities highlights the risks associated with this profession. On average, around 42 linemen lose their lives annually due to workplace hazards, mainly due to high-voltage electricity and dangerous work environments.

Understanding these trends helps improve workplace safety by identifying patterns and necessary improvements.

Annual Lineman Fatality Rate (Per 100,000 Workers)

- 2024: 38

- 2023: 40

- 2022: 36

- 2021: 34

- 2020: 42

- 2019: 32

- 2018: 31

- 2017: 39

- 2016: 29

- 2015: 41

- 2014: 35

2024: Safety Enhancements in Progress

In 2024, efforts were made to improve linemen’s safety. Despite persistent risks, advancements in technology and training contributed to reducing fatalities.

- Advanced Safety Equipment: Companies invested in the latest protective gear.

- AI-Based Monitoring: Smart technologies helped predict potential hazards.

- Mental Health Support: Programs were introduced to manage work-related stress.

2023: Mixed Outcomes

The year 2023 saw slight fluctuations in lineman fatalities, but overall safety measures showed improvement. Natural disasters, however, made working conditions more dangerous.

- Extreme Weather Conditions: Hurricanes and storms increased the risks.

- Improved Emergency Response: Companies strengthened disaster recovery plans.

- Stricter Regulations: Governments enforced stricter safety laws.

2022: Technological Advancements

Safety improved in 2022 due to various technological innovations. Although fatalities slightly decreased, new systems helped reduce accidents.

- Drones for Inspections: Reduced the need for risky manual checks.

- Enhanced Fall-Prevention Gear: New safety harnesses and equipment were introduced.

- Automated Machinery: Remote-controlled tools reduced hazardous tasks.

2021: Recovery and Adaptation

As the world recovered from the pandemic, linemen continued to face challenges. Fatalities did not rise significantly, but the previous year’s effects lingered.

- Workforce Shortages: Increased workload due to missing personnel.

- Stronger Safety Culture: Companies emphasized safety practices.

- Increased Investment in PPE: Better protective equipment was provided.

2020: A Deadly Year for Linemen

The year 2020 saw a significant rise in lineman fatalities, primarily due to the global pandemic.

- Increased Electricity Demand: More people staying home led to greater power usage.

- Staff Shortages: Many workers were sick, leading to overwork.

- Mental Health Issues: Anxiety and stress reduced adherence to safety measures.

2019: Slight Decline in Fatalities

The number of lineman deaths slightly decreased in 2019 due to several factors:

- Improved Training Programs: Companies focused on skill development.

- New Safety Technologies: Advanced tools helped prevent accidents.

2018: Safety Measures Start Showing Results

In 2018, safety initiatives began yielding results.

- Enhanced Gear: More effective protective equipment was introduced.

- Comprehensive Training Programs: Training focused on skill and safety.

- Regular Inspections: Equipment safety was ensured through frequent checks.

2017: High Fatality Rate

The year 2017 was challenging for linemen, with a significant increase in fatalities.

- Lack of Safety Regulation Enforcement: Many companies failed to enforce safety measures.

- Equipment Failures: Old and faulty tools contributed to accidents.

How Advances In Technology Can Save Lineman Lives

Technology advancements can help reduce the number of linemen fatalities each year. Enhanced safety gear and real-time monitoring systems ensure safer working conditions.

Working as a lineman is dangerous. Innovations in technology, though, offer hope for safety improvements.

Smart Wearables

Smart wearables provide linemen with real-time data. These devices monitor various health and safety metrics:

- Heart rate: Alerts if it goes too high.

- Body temperature: Signals when temperatures reach unsafe levels.

- Location tracking: Helps in quick rescue if an accident occurs.

- Fall detection: Sends instant alerts for immediate assistance.

Enhanced Training Programs

Improved training methods can make a difference. Virtual reality (VR) and augmented reality (AR) are revolutionizing lineman training:

- Simulated environments: Create realistic scenarios for practice.

- Hazard identification: Helps linemen recognize dangers.

- Safe practice: Allows for error without real-world consequences.

- Skill assessments: Offers instant feedback for improvement.

Drones For Inspection

Drones offer a safer way to inspect power lines. They reduce the need for linemen to climb poles or work at dangerous heights:

- Aerial views: Provide a comprehensive look at power lines.

- High-definition cameras: Capture detailed images for analysis.

- Remote operation: Keeps linemen on the ground.

- Quick assessments: Speed up the inspection process.

Advanced Communication Systems

Effective communication is crucial for safety. Advanced systems ensure linemen stay connected:

- Real-time updates: Keep linemen informed of changes.

- Emergency signals: Allow for immediate alerts.

- GPS tracking: Helps teams stay coordinated.

- Hands-free devices: Enable communication without compromising safety.

Predictive Analytics

Predictive analytics use data to foresee potential issues. This technology helps in maintaining safety:

- Maintenance schedules: Predict when equipment needs servicing.

- Weather monitoring: Alerts linemen to incoming storms.

- Risk assessments: Identifies high-risk areas.

- Efficiency improvements: Helps plan safer work strategies.

By integrating these technologies, the hope is to significantly reduce lineman fatalities.

The Emotional Impact Of Lineman Deaths On Families And Communities

Lineman deaths impact families and communities deeply. On average, 30 linemen die each year. The loss creates emotional and financial burdens, leaving lasting scars.

The loss of a lineman deeply affects their family and community. These brave individuals face daily dangers to keep our power running. Their deaths leave emotional scars that are hard to heal.

Impact On Immediate Family

Families of linemen often face overwhelming grief. The sudden loss is life-changing.

- Emotional Toll: Families struggle with the sudden void.

- Financial Strain: Loss of income adds stress.

- Long-term Grief: Healing can take years.

Community Reactions

Lineman deaths also impact the wider community. The loss of a local hero is felt by many.

- Public Mourning: Communities come together to honor the fallen.

- Support Systems: Neighbors rally to help the grieving family.

- Awareness Initiatives: Tragedies often lead to safety campaigns.

Psychological Support

Mental health support is essential for those affected. It can make a big difference.

Professional counseling is often needed. Families may find it hard to cope alone. Support groups offer shared experiences and comfort. Mental health services can provide crucial long-term assistance.

Memorials And Tributes

Communities often create lasting tributes. These memorials honor the linemen’s sacrifice.

- Public Ceremonies: Events to remember and honor.

- Permanent Memorials: Statues or plaques in their honor.

- Scholarships: Educational funds in their name.

The Role Of Employers

Employers play a crucial part in supporting families. Their help can be invaluable.

- Financial Assistance: Companies often provide funds.

- Counseling Services: Employers may offer mental health resources.

- Memorial Services: Organized events to honor the deceased.

The Ripple Effect

The death of a lineman sends ripples through many lives. The impact is broad and deep.

Schools, workplaces, and social circles all feel the loss. The emotional toll extends beyond immediate family. Community members often step in to offer support and solidarity.

Spotlight On National Lineman Safety Month

Every year, National Lineman Safety Month raises awareness about the dangers linemen face. Tragically, around 30 linemen die on the job annually.

National Lineman Safety Month shines a spotlight on the importance of safety for those who keep our power running. This dedicated month raises awareness about the risks linemen face daily. It encourages the adoption of safety measures to save lives.

Importance Of National Lineman Safety Month

This month is crucial for promoting safety standards. It focuses on:

- Awareness: Spreading knowledge about lineman safety.

- Training: Enhancing skills through safety programs.

- Equipment: Ensuring the use of protective gear.

- Support: Providing mental health resources for linemen.

Initiatives During National Lineman Safety Month

Various activities and programs are rolled out to emphasize safety. Some key initiatives include:

- Safety Drills: Regular practice of emergency procedures.

- Workshops: Hands-on training sessions for linemen.

- Safety Audits: Inspections to ensure compliance with safety standards.

- Public Campaigns: Educating the public about lineman safety.

The Role Of Employers In Safety

Employers play a significant role in ensuring linemen’s safety. They are responsible for:

- Providing Training: Offering comprehensive safety training programs.

- Supplying Gear: Ensuring all linemen have access to protective equipment.

- Conducting Inspections: Regularly checking equipment and working conditions.

- Promoting a Safety Culture: Encouraging a mindset of safety first.

Safety Tips For Linemen

Linemen can follow several tips to stay safe on the job. Important safety tips include:

- Wearing Protective Gear: Using helmets, gloves, and other safety equipment.

- Following Protocols: Adhering to safety procedures at all times.

- Staying Informed: Keeping updated with the latest safety guidelines.

- Reporting Hazards: Informing supervisors about any safety risks immediately.

Community Involvement In Lineman Safety

Communities can also contribute to lineman safety. They can help by:

- Supporting Campaigns: Participating in safety awareness events.

- Educating Themselves: Learning about the risks linemen face.

- Reporting Issues: Notifying authorities about potential hazards.

- Showing Appreciation: Recognizing the hard work of linemen.

National Lineman Safety Month is a reminder of the critical need for safety in this high-risk job. By focusing on awareness, training, and community involvement, we can help ensure linemen return home safely to their families.

Why Public Awareness About Lineman Risks Is Crucial

Lineman work is dangerous, with about 30 to 50 workers dying each year. Raising public awareness can help improve safety measures.

Working as a lineman is one of the most dangerous jobs. Many people are unaware of the risks these brave workers face daily. Public awareness about the dangers linemen encounter is vital for several reasons.

Enhancing Safety Measures

Understanding the risks can lead to better safety protocols.

- Improved training: More knowledge means better-prepared linemen.

- Advanced equipment: Awareness can push for safer tools.

- Policy changes: Increased attention can lead to stricter safety regulations.

- Community support: People can rally for better conditions.

Supporting Linemen And Their Families

Recognizing the dangers helps support the linemen and their families emotionally and financially.

Many linemen suffer injuries, and some lose their lives. Awareness can lead to better support systems. Communities can offer more emotional and financial help to affected families. This support can ease the burden during tough times.

Encouraging Proper Reporting

Accurate information about linemen accidents can lead to more precise data.

- Better statistics: Accurate data helps understand the problem’s scale.

- Informed policies: Data-driven policies can improve safety.

- Public interest: More reporting can keep the issue in public view.

- Funding: Awareness can lead to more funding for safety programs.

Promoting Respect And Appreciation

Awareness can boost respect for the lineman profession.

Linemen work hard to keep our lights on. Knowing their risks can help us appreciate their efforts more. Respect can lead to better working conditions and support from the community.

Increasing Public Participation

When people are aware, they can take actions to help.

- Advocacy: People can push for better safety laws.

- Donations: Funds can support linemen and their families.

- Education: Schools can teach about the importance of linemen.

- Volunteering: Communities can offer services to help linemen in need.

Understanding the risks linemen face is crucial. It can lead to better safety, support, and appreciation for these vital workers.

Frequently Asked Questions

How Many Linemen Die Each Year?

On average, around 30 to 50 linemen die each year. This number can vary based on safety practices and regulations.

Why Is The Lineman Profession Dangerous?

Linemen work with high-voltage power lines, which pose serious risks. They also face hazards like falls, electric shocks, and extreme weather conditions.

What Are The Main Causes Of Lineman Fatalities?

The main causes include electrocution, falls from heights, and being struck by objects. These hazards make the job particularly dangerous.

How Do Lineman Death Rates Compare To Other Jobs?

Lineman death rates are higher than many other professions. Their fatality rates are comparable to those in construction and fishing industries.

Conclusion

Lineman work is risky and often fatal. Many die each year. Awareness and safety measures can help. Proper training and better equipment save lives. Families and communities suffer from these losses. Let’s support linemen by promoting safety. Every life matters.

people also read

I’m not that much of a internet reader to be honest but your blogs really nice, keep it up!

I’ll go ahead and booknark your website to come back

later on. Cheers https://Www.Waste-ndc.pro/community/profile/tressa79906983/