Case Study No. 003: The Hidden Danger of Induction and Missing Gear

Working as a lineman is a profession of precision. In my 12 years on the lines, I have learned that what you don’t see is often more dangerous than what you do. This case study from my book tells the story of a brother who lost his mobility because of a silent killer and a few missing pieces of safety equipment.

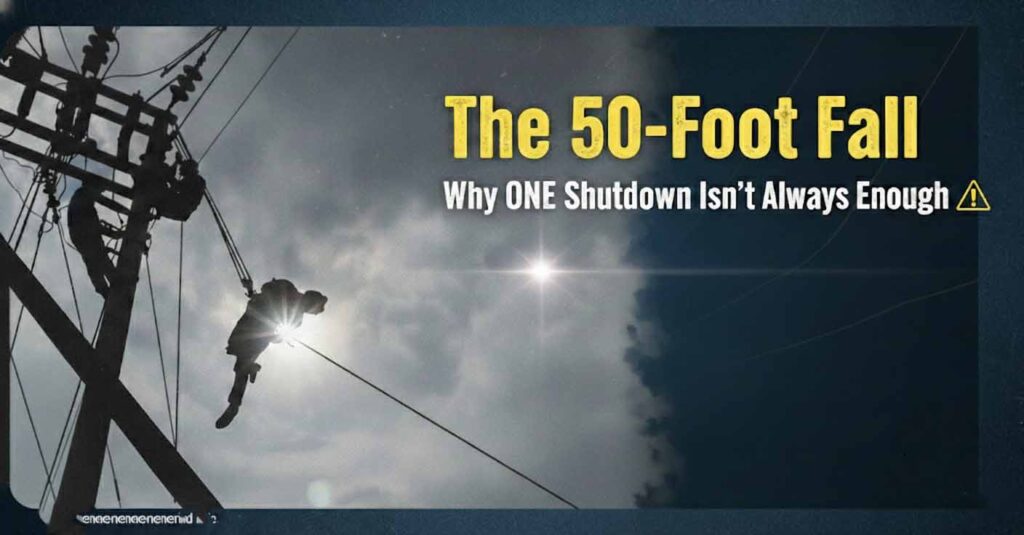

The Incident: A Storm and a 50-Foot Junction

After a severe storm, a pole on a 33 KV feeder had snapped. The repair work was located at a critical junction where two separate 33 KV lines crossed each other.

The team followed what they thought was a safe procedure:

-

A formal shut-down was taken for the specific line under repair.

-

The jumpers at the junction pole were cut to isolate the section.

-

A contractor lineman climbed the 50-foot pole to perform temporary grounding before finishing the connections.

The Accident: A Flash from the Crossing Line

⚠️ Trigger Warning: Caution: This case study contains descriptions of a severe electrical accident and life-altering injuries. It is shared for educational purposes to prevent future tragedies.

As the lineman reached the top and attempted to apply the grounding by hand, a sudden electrical discharge struck him. The shock was powerful enough to knock him unconscious instantly. He plummeted 50 feet to the ground. While he survived the fall, the impact shattered his spine, leaving him paralyzed for life.

The Technical Failure: The Silent Killer (Induction)

Even though the line he was working on was “shut down,” the crossing 33 KV line was still live. The proximity of the live line created Induced Voltage (Induction) in the dead line.

The Fatal Mistakes:

-

Partial Shutdown: A shutdown was only taken for one circuit. At a crossing point, both lines must be dead.

-

No Voltage Testing: No high-voltage detector was used to verify the line was safe before contact.

-

No Shotgun Stick: The lineman attempted grounding with his hands instead of using an insulated shotgun/safety stick. This removed the critical distance needed for safety.

-

Missing PPE: He was not wearing safety gloves, which could have provided a final layer of insulation against the induced charge.

Critical Lessons for Every Lineman

-

The Double-Shutdown Rule: When working at a junction or crossing point, always demand a shutdown for both circuits.

-

Distance is Safety: Never perform grounding by hand. Always use a shotgun stick to maintain a safe distance from potential flashes or induction.

-

Wear Your Armor: Safety gloves and full PPE are non-negotiable. They are your last line of defense.

-

Test, Don’t Guess: Use a voltage detector every single time. If it’s not tested, it’s not dead.

👷♂️ Safety Checklist for Crossing Lines:

-

[ ] Are BOTH crossing circuits shut down?

-

[ ] Did you verify with a Voltage Detector?

-

[ ] Are you using a Shotgun/Safety Stick for grounding?

-

[ ] Are you wearing certified Safety Gloves?

-

[ ] Is the shutdown confirmed via SMS or written log?

Final Word: We work to power the world, but our first priority is to return home to our families. Don’t let haste turn into a tragedy. Work safe, stay grounded.