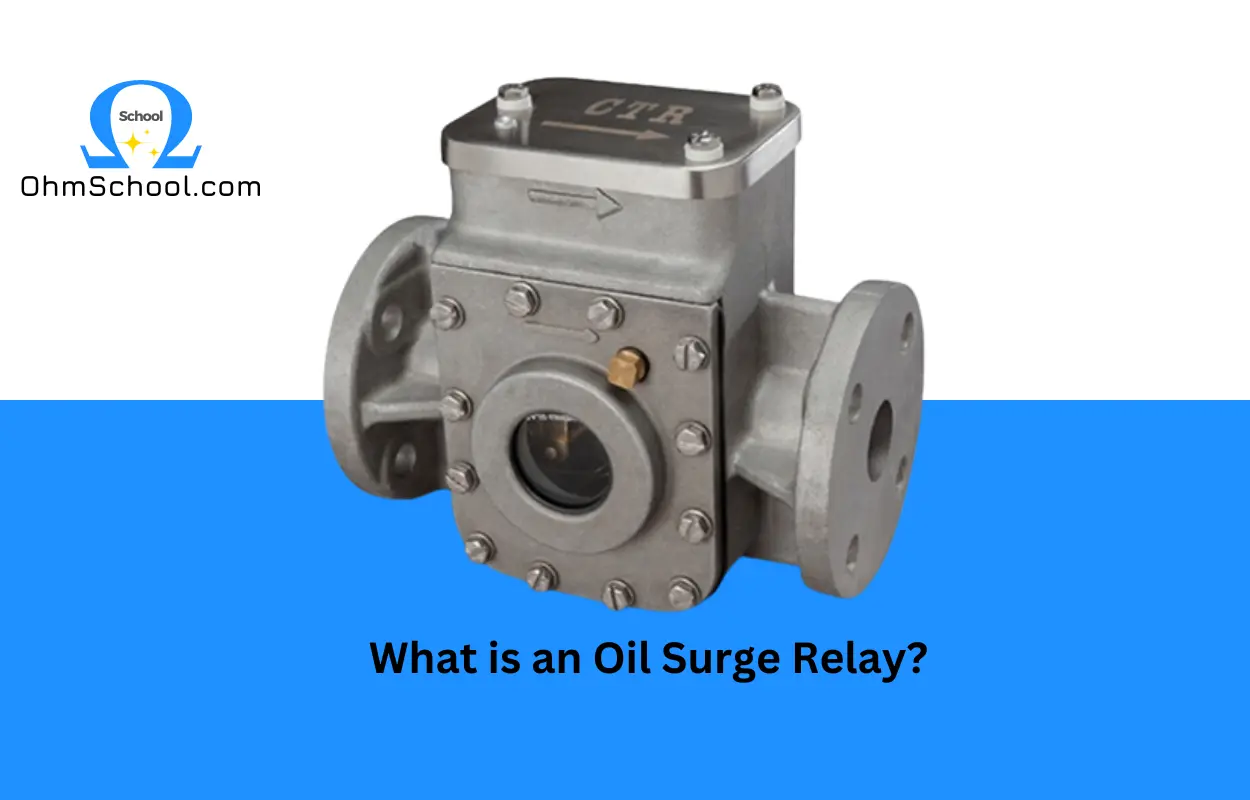

An oil surge relay is crucial for transformer safety. It protects against oil surges in power systems.

Understanding the oil surge relay is important for anyone working with transformers. This device detects sudden oil flow changes, signaling a potential problem. It can prevent damage and avoid costly repairs. The relay’s function is vital in maintaining transformer health.

Knowing how it works can save time and money. In this post, we’ll explore the basics of oil surge relays. We’ll discuss their importance and how they help protect transformers. Whether you’re an engineer or a technician, this information is useful. Let’s dive into the world of oil surge relays and their role in power systems.

What Is Oil Surge Relay

The Oil Surge Relay (OSR) plays a crucial role in the protection and efficient operation of transformers. This device is essential in detecting abnormal oil flow within the transformer, ensuring that any potential issues are identified and addressed promptly. Understanding what an Oil Surge Relay is and how it functions is key for anyone involved in the maintenance and operation of electrical systems.

Purpose Of The Relay

The primary purpose of the Oil Surge Relay is to monitor the oil flow within a transformer. When a fault occurs inside the transformer, such as a short circuit or an electrical fault, there is a sudden surge in oil flow. The relay detects this abnormal surge and activates an alarm or trips the transformer to prevent further damage.

Here are the key purposes of an Oil Surge Relay:

- Fault Detection: Identifies internal faults by detecting abnormal oil movement.

- Protection: Protects the transformer from severe damage by triggering alarms or tripping mechanisms.

- Safety: Ensures the safety of the equipment and personnel by preventing catastrophic failures.

In essence, the Oil Surge Relay acts as a safeguard, ensuring that any internal issues within the transformer are quickly addressed. This helps in maintaining the longevity and efficiency of the transformer, reducing the risk of costly repairs or replacements.

Components Involved

The Oil Surge Relay consists of several key components, each playing a vital role in its operation. Understanding these components can help in better comprehending how the relay functions.

| Component | Description |

|---|---|

| Relay Body | Houses all the internal parts and provides structural support. |

| Float Mechanism | Detects changes in oil levels and activates the relay when necessary. |

| Contacts | Electrical contacts that close or open circuits based on the relay’s activation. |

| Pressure Sensor | Senses changes in pressure due to oil surges and triggers the relay. |

| Alarm Circuit | Activates alarms to alert personnel of potential issues. |

Each component of the Oil Surge Relay works together to ensure that any abnormal conditions within the transformer are detected and addressed promptly. The float mechanism, for instance, is sensitive to changes in oil levels, while the pressure sensor detects variations in pressure. These components collectively ensure the relay performs its protective functions efficiently.

How It Works

An Oil Surge Relay is a crucial component in electrical transformers. It helps protect the transformer from internal faults. Understanding how it works can help ensure the reliability and safety of your electrical systems. Let’s delve into the mechanisms and key functions of this device.

Mechanism Of Action

The Oil Surge Relay operates by detecting changes in oil flow within the transformer. When a fault occurs, it causes a rapid increase in oil pressure. This triggers the relay to activate protective measures.

Here’s a step-by-step breakdown of its mechanism:

- Oil Movement: Normally, oil circulates within the transformer to cool it.

- Fault Detection: During a fault, such as an internal short circuit, the oil movement changes.

- Pressure Build-up: The fault causes a sudden increase in oil pressure.

- Relay Activation: The relay senses this pressure surge and activates.

- Trip Signal: It sends a trip signal to disconnect the transformer, preventing damage.

Key Components:

| Component | Function |

|---|---|

| Pressure Sensor | Detects changes in oil pressure |

| Relay Mechanism | Activates protective measures |

| Trip Circuit | Disconnects the transformer |

Key Functions

The Oil Surge Relay serves several important functions to safeguard the transformer:

- Fault Detection: It detects internal faults quickly.

- Transformer Protection: It prevents damage by disconnecting the faulty transformer.

- System Reliability: Ensures the overall reliability of the electrical system.

Let’s look at these functions in more detail:

Fault Detection: The relay continuously monitors the oil flow. Any abnormal surge in pressure triggers its mechanism. This quick detection helps in minimizing damage.

Transformer Protection: By disconnecting the transformer during a fault, the relay prevents further damage. This action helps in avoiding costly repairs and downtime.

System Reliability: Regular operation of the relay ensures that the electrical system remains stable. It helps in maintaining the efficiency and longevity of the transformer.

In conclusion, the Oil Surge Relay plays a vital role in protecting electrical transformers. Its mechanisms and functions are essential for ensuring safety and reliability in electrical systems.

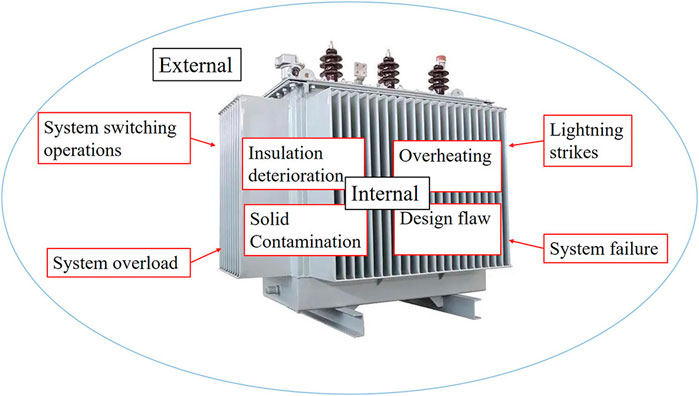

Learn about the causes of transformer issues and how devices like oil surge relays can prevent damage.

Importance In Industry

Oil Surge Relays play a crucial role in various industries, particularly in the electrical and power sectors. Their primary function is to detect and manage oil surges in transformers, ensuring the system operates smoothly. The significance of Oil Surge Relays in industry cannot be overstated, as they contribute to both safety and operational efficiency.

Safety Enhancements

Oil Surge Relays significantly enhance safety in industrial settings. They monitor oil levels and detect any abnormal surges, which can indicate potential faults. By providing early warnings, these relays prevent catastrophic failures and reduce the risk of fires.

Key safety benefits include:

- Early Fault Detection: Quickly identifies issues before they escalate.

- Fire Prevention: Minimizes the risk of oil-related fires.

- Protective Mechanisms: Triggers alarms and shutdowns to safeguard equipment and personnel.

Below is a table summarizing the safety features:

| Feature | Benefit |

|---|---|

| Early Fault Detection | Prevents equipment damage |

| Fire Prevention | Reduces fire hazards |

| Protective Mechanisms | Ensures personnel safety |

By incorporating Oil Surge Relays, industries can maintain a safer working environment. This proactive approach to safety helps in avoiding costly repairs and downtime.

Operational Efficiency

Operational efficiency is another critical aspect where Oil Surge Relays prove invaluable. They ensure transformers and other equipment run optimally, reducing unnecessary energy consumption and wear.

How Oil Surge Relays enhance operational efficiency:

- Continuous Monitoring: Keeps track of oil levels and pressure.

- Automatic Adjustments: Makes real-time adjustments to maintain optimal operation.

- Reduced Downtime: Prevents unexpected breakdowns, ensuring continuous operation.

Here is a table highlighting operational efficiency benefits:

| Feature | Benefit |

|---|---|

| Continuous Monitoring | Ensures consistent performance |

| Automatic Adjustments | Optimizes energy use |

| Reduced Downtime | Maintains production schedules |

With Oil Surge Relays, industries can achieve higher efficiency, leading to cost savings and better resource management. This focus on operational efficiency supports long-term sustainability and reliability.

Credit: m.youtube.com

Installation Process

Oil Surge Relays are crucial components in the safety and efficiency of transformers. Their primary function is to detect and respond to oil surges that might indicate internal faults. Proper installation of an Oil Surge Relay ensures it operates effectively, providing essential protection for your electrical equipment. This guide will walk you through the installation process.

Preparation Steps

Proper preparation is essential for the successful installation of an Oil Surge Relay. Follow these steps to ensure everything is ready:

- Gather necessary tools: Ensure you have all required tools such as screwdrivers, wrenches, and measuring instruments.

- Review the manual: Read the manufacturer’s manual carefully to understand the specific requirements and recommendations for your Oil Surge Relay model.

- Inspect the relay: Check the Oil Surge Relay for any visible damage. Ensure all components are intact.

- Check the transformer: Inspect the transformer where the relay will be installed. Ensure it is in good condition and free of contaminants.

Once the tools and materials are ready, proceed with the following:

- Mount the relay: Securely mount the Oil Surge Relay on the transformer, ensuring it is positioned correctly.

- Connect the pipes: Attach the necessary pipes to the relay. Ensure the connections are tight to prevent leaks.

- Electrical connections: Connect the relay to the control panel. Follow the wiring diagram provided in the manual.

- Test the relay: Perform a functional test to ensure the relay is working correctly. Check for proper operation and response times.

Best Practices

Adhering to best practices during installation ensures the longevity and reliability of your Oil Surge Relay. Consider the following tips:

- Use quality materials: Always use high-quality materials and components to avoid premature failures.

- Follow safety protocols: Wear appropriate personal protective equipment (PPE) and follow safety guidelines to prevent accidents.

- Regular maintenance: Schedule regular maintenance checks to ensure the relay remains in optimal condition.

- Document the process: Keep detailed records of the installation and any subsequent maintenance activities.

Additionally, ensure that:

- All connections are secure: Check all electrical and mechanical connections for tightness and proper contact.

- Environmental conditions: Install the relay in an environment that meets the specified temperature and humidity conditions.

- Training: Provide adequate training for personnel responsible for the relay’s operation and maintenance.

Follow these best practices to maximize the efficiency and lifespan of your Oil Surge Relay, ensuring it performs its critical protective functions effectively.

Explore the working principles of power transformers and the role of oil surge relays in maintaining safety.

Common Issues

Oil Surge Relays are crucial in protecting transformers from faults and damages. They detect oil movement due to faults and trip the circuit to prevent further issues. However, like all devices, they can encounter problems. Understanding common issues helps in maintaining their effectiveness.

Troubleshooting Tips

When Oil Surge Relays encounter issues, quick troubleshooting is essential. Here are some common problems and tips to address them:

- Relay Not Tripping: Check the relay settings. Ensure the trip settings are correct and not too high or too low.

- Frequent False Trips: Inspect for possible oil turbulence. Make sure the relay is free from obstructions and vibrations.

- Oil Leakage: Examine the relay seals. Replace any worn-out seals to prevent oil leakage.

- Electrical Failures: Check for loose connections. Tighten any loose wires and ensure all connections are secure.

Here is a table summarizing these issues and their solutions:

| Issue | Solution |

|---|---|

| Relay Not Tripping | Verify and adjust trip settings |

| Frequent False Trips | Check for oil turbulence and obstructions |

| Oil Leakage | Inspect and replace seals |

| Electrical Failures | Tighten loose connections |

Regular maintenance and inspection can help address these issues promptly. Always follow manufacturer guidelines for troubleshooting.

Preventative Measures

Preventative measures are key to ensuring the longevity of Oil Surge Relays. Here are some steps to keep them in optimal condition:

- Regular Inspections: Schedule regular checks to identify potential issues early. Inspect the relay for any signs of wear or damage.

- Proper Installation: Ensure the relay is installed correctly. Follow the manufacturer’s guidelines for installation to avoid future problems.

- Routine Testing: Conduct routine tests to verify the relay’s functionality. Testing helps ensure the relay operates correctly during faults.

- Clean Environment: Keep the relay in a clean environment. Dust and debris can affect its performance.

Following these measures can help prevent common issues and extend the relay’s lifespan. Here is a brief overview:

| Measure | Benefit |

|---|---|

| Regular Inspections | Early issue detection |

| Proper Installation | Avoid future problems |

| Routine Testing | Ensures functionality |

| Clean Environment | Prevents performance issues |

By adopting these preventative measures, you can maintain the effectiveness of your Oil Surge Relays and ensure the safety of your transformers.

Credit: www.youtube.com

Maintenance Guidelines

An Oil Surge Relay (OSR) plays a crucial role in the protection of transformers by detecting oil surges that may indicate faults. Regular maintenance is essential to ensure its proper functioning and longevity. Follow these maintenance guidelines to keep your OSR in optimal condition.

Routine Checks

Routine checks are important to ensure your OSR is functioning correctly. Perform these checks regularly to avoid unexpected failures and ensure reliability:

- Visual Inspection: Check for any signs of damage, corrosion, or leaks. Ensure the relay is clean and free from dust and debris.

- Operational Test: Test the relay by simulating an oil surge to confirm it triggers the alarm and trip circuits as expected.

- Electrical Connections: Inspect all electrical connections for tightness and integrity. Loose connections can lead to malfunctions.

- Oil Level Check: Ensure the oil level in the conservator tank is within the recommended range. Low oil levels can affect the relay’s performance.

It’s also beneficial to keep a maintenance log. Record the date, findings, and actions taken during each check. This helps track the relay’s condition over time and identify any emerging patterns or issues.

Replacement Indicators

Knowing when to replace your OSR can prevent transformer damage and costly downtime. Look for these indicators:

- Frequent False Alarms: If the relay triggers alarms frequently without any actual oil surge, it may be faulty and need replacement.

- Inconsistent Performance: If the relay fails to operate consistently during tests, consider replacing it.

- Physical Damage: Any visible signs of damage, such as cracks or severe corrosion, indicate the need for replacement.

- Aging: Relays have a specified lifespan. If your OSR is approaching or has exceeded this lifespan, plan for a replacement.

These indicators help ensure reliable operation of your transformer protection system. Regularly assess the condition of your OSR and replace it when necessary to maintain system integrity.

Technological Advances

Oil Surge Relay (OSR) technology has seen remarkable advancements in recent years. These advancements aim to enhance the efficiency, reliability, and safety of OSR systems. The introduction of smart relay systems and integration with IoT are two significant technological strides worth noting.

Smart Relay Systems

Smart relay systems bring a new level of intelligence to Oil Surge Relays. These systems use advanced algorithms and sensors to monitor the relay’s performance continuously. Here are some key features of smart relay systems:

- Real-time Monitoring: Constantly checks the status of the relay and the associated equipment.

- Predictive Maintenance: Uses data analytics to predict potential failures before they occur.

- Self-diagnosis: Identifies and reports any abnormalities or faults within the system.

- Enhanced Safety: Provides quicker response times to prevent major issues.

These features improve the overall reliability and efficiency of the relay systems. For instance, real-time monitoring allows for immediate detection of oil leaks or pressure surges. Predictive maintenance reduces downtime by addressing issues before they lead to failures. This proactive approach not only saves costs but also ensures the longevity of the equipment.

Furthermore, smart relay systems are user-friendly. They often come with intuitive interfaces that make it easier for operators to understand and manage the system. This ease of use is crucial for maintaining the system’s efficiency and reliability.

Integration With Iot

The integration of Oil Surge Relays with the Internet of Things (IoT) takes their functionality to another level. IoT enables the relay systems to connect and communicate with other devices and systems. Here are some benefits of IoT integration:

- Remote Monitoring: Allows operators to monitor the relay systems from anywhere in the world.

- Data Collection: Gathers vast amounts of data for analysis and performance improvement.

- Automated Controls: Enables automatic adjustments based on real-time data.

- Improved Decision-Making: Provides insights that help in making informed decisions.

Remote monitoring is particularly beneficial in critical infrastructure where timely response is crucial. Operators can receive alerts and take necessary actions without being physically present at the site. This feature enhances the safety and efficiency of the operations.

Data collection and analysis through IoT provide valuable insights into the system’s performance. These insights can be used to optimize operations, reduce energy consumption, and improve the overall efficiency of the relay systems. Automated controls further enhance the system’s reliability by making real-time adjustments based on the data collected.

Overall, the integration of Oil Surge Relays with IoT represents a significant technological advancement. It makes the relay systems smarter, more efficient, and more reliable, ensuring optimal performance and safety.

Understand the importance of current limiting devices in conjunction with oil surge relays for transformer protection.

Future Trends

Oil surge relays are crucial components in transformer protection systems. They detect oil movement within transformers, preventing severe damages. As technology advances, the future trends of oil surge relays are becoming a focal point for many industries. These trends are shaping the market and driving innovations that promise to enhance efficiency and reliability.

Market Predictions

The oil surge relay market is set for substantial growth. Several factors contribute to this positive outlook:

- Increased demand for electricity: As global energy needs grow, more transformers are needed, driving up the demand for oil surge relays.

- Renewable energy integration: With more renewable energy sources being integrated into power grids, the need for reliable transformer protection rises.

- Technological advancements: Emerging technologies are making oil surge relays more efficient and easier to maintain.

- Regulatory requirements: Stringent safety and environmental regulations increase the adoption of advanced protection systems.

According to recent studies, the market for oil surge relays is expected to grow at a compound annual growth rate (CAGR) of 5% over the next decade. This growth is driven by the modernization of power infrastructure and the need for more reliable power transmission. The following table provides an overview of the expected market growth:

| Year | Market Value (in billion USD) | Growth Rate (%) |

|---|---|---|

| 2023 | 1.2 | 5% |

| 2025 | 1.32 | 6% |

| 2030 | 1.77 | 7% |

Innovations On The Horizon

The future of oil surge relays is bright with many innovations on the horizon. Some key advancements include:

- Smart relays: Integration of IoT (Internet of Things) technology allows real-time monitoring and data analysis.

- Self-diagnostic features: Relays with self-diagnostic capabilities can detect faults and notify operators before a failure occurs.

- Improved materials: Use of advanced materials for better durability and performance.

- Energy-efficient designs: New designs aim to reduce energy consumption and enhance overall efficiency.

These innovations will not only enhance the performance of oil surge relays but also reduce maintenance costs and downtime. Smart relays, for instance, offer significant benefits:

- Real-time data collection

- Predictive maintenance

- Enhanced safety

Another exciting development is the use of advanced sensors. These sensors can detect even the smallest changes in oil movement, providing early warnings of potential issues. This leads to quicker response times and less damage to transformers.

Overall, the future trends in oil surge relays point towards more intelligent, efficient, and reliable systems. These advancements will play a crucial role in the ongoing evolution of power distribution and transformer protection.

Credit: ohmschool.com

Frequently Asked Questions

What Is An Oil Surge Relay?

An oil surge relay is a protective device used in transformers. It detects sudden oil movements. This helps prevent damage from internal faults.

How Does An Oil Surge Relay Work?

An oil surge relay works by detecting abnormal oil flow. It triggers an alarm or shuts down the transformer. This prevents potential damage.

Why Is An Oil Surge Relay Important?

An oil surge relay is crucial for transformer safety. It detects internal faults early. This helps avoid costly repairs and downtime.

Where Is An Oil Surge Relay Used?

Oil surge relays are used in electrical transformers. They are common in power plants and substations. Their role is to ensure operational safety.

Conclusion

Oil surge relays play a vital role in transformer safety. They detect oil leaks and prevent damage. Regular maintenance is crucial for their efficiency. Always check for signs of wear and tear. This keeps your equipment running smoothly. Understanding their function helps you take timely action.

Protect your transformers with reliable oil surge relays. This ensures long-term performance and safety. Stay informed and proactive in maintenance. Your equipment and investments will thank you.