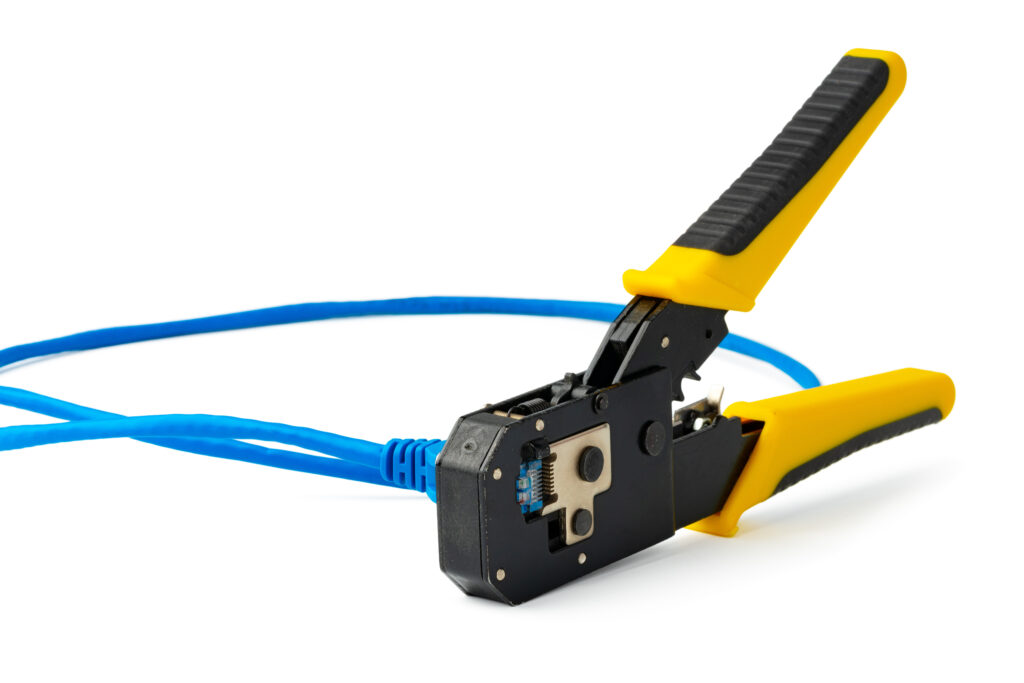

A cable crimper is a tool used to connect cables and wires with various connectors. It applies pressure to deform the connector and secure it to the cable.

In the realm of electrical installations and network setups, cable crimpers play an essential role, ensuring strong, reliable connections between cables and connectors. These tools come in various types and sizes, each designed to work with specific connectors and cable gauges, from ethernet and coaxial cables to larger power cables.

Easy to operate and highly practical, cable crimpers are indispensable for electricians, network technicians, and DIY enthusiasts looking to create custom cable lengths. Precision and durability are key when choosing a crimper, as the integrity of electrical and data transmissions can hinge on the quality of the connection made.

The Significance Of Cable Crimping

Cable crimping plays a crucial role in electrical and networking applications. It ensures that cables and wires maintain a sturdy, reliable connection. Whether in large-scale industrial settings or simple home repairs, understanding the significance of cable crimping is key to success.

Ensuring Reliable Electrical Connections

Consistent electricity flow depends on solid wire connections. Cable crimpers are the go-to tools that professionals use to create these connections. By pressing the metal connector around a wire’s stripped end, a crimping tool guarantees a strong, secure bond.

- Improves Connection Quality: A good crimp can be as strong as the wire itself.

- Combats Corrosion: Proper crimping seals out moisture, which reduces the risk of corrosion.

- Ensures Safety: A firm crimp prevents loose wires, reducing the chance of electrical malfunctions.

The Role In Professional And Diy Projects

Cable crimpers are essential whether you’re a certified electrician or a home project enthusiast. They are versatile tools used across various tasks.

| Professionals Use Crimpers For: | DIY Projects Might Include: |

|---|---|

| Secure wire terminations in panels | Fixing a broken electronic toy |

| Creating custom-length network cables | Installing a new light fixture |

| Wiring control systems for automation | Assembling battery cables for cars |

Accessibility and ease of use also make crimping tools ideal for both professional and DIY use. This multi-faceted tool ensures every project benefits from reliable, high-quality connections.

Credit: www.amazon.com

Key Types Of Cable Crimpers

Every electrician and DIY enthusiast understands the importance of a good cable crimper. These essential tools create a tight and secure connection between wires and connectors. Let’s dive into the key types of cable crimpers that professionals and hobbyists use to ensure a flawless electrical job.

Manual Crimping Tools

Manual crimping tools are the most basic yet essential type. They require physical force to operate but offer precision and control. Ideal for smaller jobs, these crimpers are both affordable and portable. Users typically squeeze the handles together to crimp a connector onto a wire. Popular models include:

- Simple hand crimpers: Best for occasional use or light-duty work.

- Benchtop crimpers: These provide more leverage and are great for repetitive tasks.

Hydraulic And Ratchet Crimpers

For those who seek more power and less strain on their hands, hydraulic and ratchet crimpers are the answer. These tools often come with interchangeable dies and offer consistent crimping force. They are suitable for heavy gauge wires and large projects. Characteristics include:

| Type | Use Case |

|---|---|

| Hydraulic Crimpers | Ideal for high-volume, high-pressure crimping. |

| Ratchet Crimpers | They ensure a full crimp cycle before release to avoid incomplete crimps. |

Automated Crimping Machines

In mass production environments, automated crimping machines are essential. These machines are fast, efficient, and maintain consistent quality. With minimal human intervention, they reduce the chance of errors and speed up the crimping process significantly. Here’s what they offer:

- Speed: They can process thousands of crimps per hour.

- Precision: Automated machines deliver uniform crimps every time.

- User-friendliness: Most feature touchscreens and programmable settings.

Selecting The Right Cable Crimper

Selecting the right cable crimper is essential for creating strong, reliable connections in wiring tasks. This process involves considering several factors. From size and type to quality and durability, finding the perfect match optimizes your work. Ensure your connections are secure with the ideal tool.

Assessing Crimper Size And Type

- Inspect the project requirements to determine the crimper size needed. Different gauges demand specific tools.

- Choose between manual and hydraulic crimpers based on the task’s frequency and volume.

- Evaluate ergonomics and ease of use to prevent hand fatigue, especially for repetitive jobs.

Crimper Quality And Durability Concerns

Invest in higher-quality crimpers for longer-lasting performance. Key points include:| Feature | Benefit |

|---|---|

| Hardened steel construction | Ensures sturdiness and longevity |

| Rust-resistant finish | Maintains functionality over time |

| Comfortable grips | Reduces strain on hands |

Compatibility With Connectors And Terminals

Confirm the crimper’s compatibility with your connectors and terminals. Do this to avoid poor connections. Match the crimper to the specific types and sizes of connectors you plan to use. Ensure optimal performance and avoid any connection issues.

Credit: www.amazon.com

Crimping Terminals And Connectors

Master the art of securing wires with a cable crimper! Crimping terminals and connectors is a crucial skill. It creates reliable electrical connections. Proper technique is key. Let’s explore the right way to crimp.

Preparation Steps Before Crimping

Getting ready to crimp is just as important as the crimp itself.

- Choose the correct crimper for your terminal type and wire size.

- Gather materials: terminals, connectors, wire stripper.

- Strip the wire to the recommended length without nicking the strands.

- Inspect for any damage on terminals and insulation.

- Place the terminal into the crimper jaw correctly.

Step-by-step Crimping Process

- Insert the stripped wire end into the terminal.

- Ensure wires reach the end of the connector barrel.

- Position the crimper perpendicular to the terminal.

- Squeeze the crimper handles firmly until they release.

- Check the crimp to confirm it’s tight and secure.

- Tug gently on the wire to ensure it’s held firmly.

Common Mistakes To Avoid

Take note of these errors to avoid a faulty crimp:

- Wrong crimper size: This results in loose or damaged terminals.

- Over or under-crimping: This can weaken the connection.

- Ignoring insulation: May lead to electrical shorts.

- Uneven stripping: Causes poor connections.

- Forgetting to inspect: Before and after crimping is a must.

Essential Features Of Top-quality Crimpers

For anyone who works with cables, a cable crimper is a must-have tool. A high-quality crimper ensures strong, reliable connections. Yet, not all crimpers are the same. Certain features separate the best crimpers from the rest. Let’s dive into these essential features.

Ergonomic Design Considerations

Comfort matters in any tool, and crimpers are no different. An ergonomic design reduces strain during repetitive use. Top crimpers boast features like cushioned handles and a grip that conforms to the hand. This means less fatigue and more productivity on the job.

Adjustment Mechanisms And Calibration

Precision is key for secure crimps. Adjustment mechanisms allow precise control over the crimping process. Calibrated settings ensure consistent results every time. These features are vital for handling various cable sizes and types without damaging the wire.

Material And Build For Longevity

The build quality of a crimper dictates its lifespan. Durable materials like high-carbon steel resist wear and tear. Quality crimpers often have a rust-resistant finish. This makes them tough enough for heavy-duty use and guarantees a tool that lasts for years.

Safety Tips For Cable Crimping

Cable crimping creates reliable connections for electrical projects. Like all electric work, it requires caution. To stay safe, always follow these key safety tips.

Personal Protective Equipment

Personal safety begins with the right gear. Always wear safety glasses to protect your eyes from metal filings or wire strands.

- Gloves prevent cuts and scrapes. Choose ones that offer good dexterity.

- Protect ears with earplugs in noisy environments.

- Wear a dust mask if working in a dusty area. This keeps your lungs clear.

Electrical Safety Precautions

Working with cables can expose you to current. Turn off the power before starting. Use a voltage tester to ensure no current runs through the cables.

| Procedure | Reason |

|---|---|

| Check cords for damage | Prevents electrocution |

| Avoid wet areas | Water conducts electricity |

| Use insulated tools | Added safety from shocks |

Maintaining Your Tools

Well-maintained tools make safe tools. Inspect crimpers regularly. Look for signs of wear or damage before they cause problems.

- Clean your tools after each use.

- Store them in a dry place.

- Get professional repairs if needed.

Follow these steps for safe cable crimping.

Troubleshooting Common Crimping Problems

Having trouble with your cable crimping? Whether you’re a seasoned electrician or a DIY enthusiast, crimping issues can be a real headache. Let’s dive into some common crimping problems and find out how to fix them quickly and efficiently.

Identifying Poor Crimp Connections

Spotting a bad crimp connection is crucial. Here are signs to look out for:

- Loose connections: The wire shouldn’t wiggle.

- Visible gaps: A perfect crimp leaves no space between the wire and the connector.

- Insulation damage: Crimping must not cut through the insulation.

A multimeter test can confirm a bad crimp. Look for inconsistent resistance reading.

Solving Crimper Malfunction Issues

Crucial steps to fix a malfunctioning crimper:

- Check the crimper’s dies. They must align properly.

- Clean any debris that might cause jams.

- Oil the joints if the crimper is stiff.

- If these don’t work, consult the manual or seek professional help.

Dealing With Damaged Wires And Terminals

Occasionally, wires or terminals might get damaged during crimping. Here’s how to handle that:

| Problem | Solution |

|---|---|

| Stripped wires: | Cut back to clean wire; re-crimp with a fresh terminal. |

| Crushed terminals: | Remove the whole terminal. Strip wire end. Use a new terminal. |

| Burnt wires: | Cut the burnt section. Strip and crimp with an undamaged terminal. |

Enhancing Your Skills With Advanced Techniques

Mastering the use of a cable crimper is a valuable skill. Gaining the expertise to create secure, reliable connections can elevate a professional’s craft. Advanced techniques can sharpen skills, ensuring a competitive edge in the industry.

Learning From Expert Crimpers

Observation and hands-on practice with seasoned crimpers provide invaluable insights. Witness different approaches and adapt unique methods:

- Shadow skilled technicians during their routine to see best practices in action.

- Ask questions to understand the reasoning behind their techniques.

- Participate in practical sessions where experts give step-by-step guidance.

Training Courses And Certifications

Formal education is crucial for comprehensive learning:

- Enroll in accredited courses to cover both theory and practical skills.

- Attain certifications recognized in your field to showcase proficiency.

- Regularly update qualifications to keep pace with technological advancements.

Keeping Abreast With Industry Standards

Standards evolve; stay informed:

- Read industry publications for the latest best practices and standards.

- Engage with online communities of professionals for tips and updates.

- Attend workshops and seminars for hands-on experience with new tools and materials.

The Future Of Cable Crimping Tools

The cable crimping industry is on the crest of transformation. Advanced tech and automation are reshaping how we secure cable connections. This surge promises faster, more reliable, and efficient outcomes. Let’s explore the thrilling advancements in this field.

Innovations In Crimping Technology

Technology is revamping the traditional crimping tool. Modern features include:

- Improved ergonomic designs that reduce hand fatigue

- Digital displays for precise control and feedback

- Adjustable crimping forces for diverse cable sizes

New materials also make tools lighter and stronger. Expect more durable and long-lasting crimpers.

The Shift Towards Automation

Manual labor is giving way to automated solutions. Automated crimping machines offer:

- Consistent pressure application

- Ability to handle large volumes with ease

- Reduction in human error

Less waste and higher productivity are the hallmarks of these automated systems.

Impacts On Quality And Efficiency

With tech advancements, quality and efficiency soar. Key impacts include:

| Aspect | Impact |

|---|---|

| Precision | Exact crimping ensures optimal performance |

| Speed | Tasks complete quicker, saving valuable time |

| Waste Reduction | Fewer mistakes mean less material waste |

The right tool can therefore enhance overall project outcomes significantly.

Frequently Asked Questions Of Cable Crimper

What Is A Cable Crimper Used For?

A cable crimper is a tool designed to join two pieces of metal, typically electrical connectors, by deforming one or both of them to hold each other. The joint it creates is called a crimp.

How Do You Properly Use A Cable Crimper?

To use a cable crimper, first, strip the wire to the correct length. Then, place the connector in the crimper’s die. Squeeze the crimper handles together until the connector is tightly secured onto the wire.

What Types Of Cable Crimpers Are Available?

Cable crimpers come in various types, including manual, hydraulic, and ratcheting models. Each type serves different crimping needs, from small electronics to large industrial cables.

Can A Cable Crimper Be Used On All Cables?

Not all crimpers are universal; checking compatibility with specific cable sizes and connector types before use is essential to ensure a proper crimp.

Conclusion

Selecting the right cable crimper is vital for ensuring secure, reliable connections in electrical work. Carefully consider functionality, durability, and compatibility with your project’s cables. By investing in a quality tool, you’ll achieve professional results every time. Remember, a well-crimped cable is the backbone of any robust electrical system.

Happy crimping!